PRODUCTION AND TEHNOLOGICAL POSSIBILITIES

- production of electronic modules, anti-jamming throttles, cables and electronic products for the household

- production of high-technology products, which are competitive to those, manufactured by leading companies in the field of electronics (reconstruction of the production area, financed according to contract with MOAP and “Development of human resources and labor encouragement” program

The technological process includes:

- automated assembly of SMD electronic components

- assembly of electronic elements standard performance, cables and mechanical details

- casing and encapsulation of electronic units

- visual and functional control

- packaging and shipping of ready products

Modular Placement Machine

| PCB exchange time |

| about 4.0 s (When no components are placed on the back of the PCB) |

| PCB dimensions (mm) | L 50 × W 50 to L 460 × W 360 |

| High-speed head | 12 nozzles |

| Max. speed | 0.144 s/chip (Type A-2) |

| Placement accuracy | ± 40 µm/chip (Cpk1) |

| Component dimensions (mm) | (01005”) 0402 chip *1 to L 12 × W 12 × T 6.5 |

| High-flexibility head | LS8 nozzles |

| Max. speed | 0.19 s/chip(Type A-0) |

| Placement accuracy | ± 50 µm/chip, ± 35 µm/QFP 24 mm to 50 mm, ± 50 µm/QFP<24 mm (Cpk1) |

| Component dimensions (mm) | (0201”) 0603 chip to L 32 × W 32 × T 8.5 |

| Multi-functional head | 3 nozzles |

| Max. speed | 0.8 s/QFP (Type B-0) |

| Placement accuracy | ± 35 µm/QFP (Cpk1) |

| Component dimensions (mm) | (0201”)0603 chip to L 100 × W 90 × T 25 |

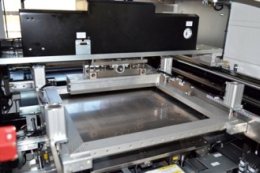

Screen Printer

| PCB dimensions (mm) | L 50 × W 50 to L 510 × W 460 (L 330 × W 250) |

| Cycle time | 8.0 s + printing tim |

| Repeatability | ±12.5 μ |

| Screen frame dimensions | L 736 × W 736 L 650 × W 550 (Horizontally oriented) |

| L 550 × W 650 (Vertically oriented) L 600 × W 550 (Horizontally oriented) |

Reflow soldering oven

| Maximum Board Width Standard | 20" (50.8 cm) |

| Top Heating Zones | 7 |

| Bottom Heating Zones | 7 |

| Number of Cooling Zones Standard | 1 |

| Temperature Range Standard | 25-350° C |

| Heated Length | 72" (183 cm) |

| Maximum Conveyor Speed | 74"/Min (188 cm/min.) |

Cables

JQ-1- Full automatic terminal crimping machine (both ends)

NCPP-25 – Numerical

cortrol precision press

MECHANICS Department – Litakovo village.

- versatile machines, allowing manufacturing of dies and press moulds and tooling equipment

- wire-erosion and electrical discharge machines

- milling machines, automatic and eccentric presses

- cam lathes and extrusion machines

- Production lines for manufacturing of power switches for hand-held power tools

COATINGS Department

- installed high-technology equipment by leading English, Swiss and Austrian companies - allows laying of high-quality galvanic and electrostatic coatings

- The classical galvanization is carried out by frame and drum lines

- Galvanic coatings production line

- The quality of the galvanic coatings is controlled by the technical laboratory in the department

- Local WWTP